|

| November 17, 2015 | Volume 11 Issue 43 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Ceramic air valves work every time

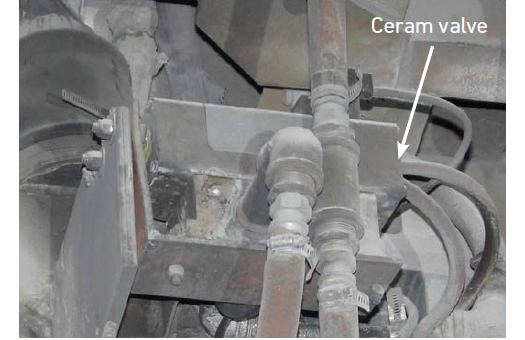

The AVENTICS Ceram valve uses sliding ceramic plates to control the air flow direction, allowing it to operate in harsh conditions.

"The guys in the pot rooms love the reliability and strong operation of the new Ceram valves, because the jackhammers are more powerful and work every time."

This is a quote from the Operations Superintendent of Noranda Aluminum in New Madrid, MO. Up until recently, air valve failures were a daily occurrence at this mill, costing thousands of dollars per day in parts, labor, and lost production. Today, the problems have disappeared, going from 60 failures per month to zero in one application.

The situation

Noranda Aluminum is a large smelting operation situated on the Mississippi River in southern Missouri. This plant uses alumina oxide to produce quality aluminum for industry. The raw product comes in on barges and is offloaded and conveyed to the mill, where it is turned into pure aluminum. The final product is then shipped to different regions of the country and used to make car parts, foil, and other products we use in our everyday lives.

The expected service life of the AVENTICS Ceram valve exceeds 150 million cycles.

Producing aluminum from the ore is a detailed and costly process, and a lot must happen between the ore barge and the mill's shipping docks. It requires the use of large and complicated equipment, heat, chemistry, manpower, and a huge amount of know-how. The aluminum is produced in large pots that are heated to a high temperature. Here the alumina oxide is mixed with other elements and chemicals, heated, and carefully blended into molten aluminum.

A hard crust forms on top of the pots during this process. This crust must be broken periodically so anodes made of carbon can be exchanged. Positive electric charge flows through these electrodes, creating the heat that melts the ore. The anodes are consumed in the process and must be replaced with new elements on a periodic schedule. A critical apparatus used to replace the anodes is a crane that functions as a crust breaker. The crane has a pneumatic jackhammer that is used to break the crust that forms on top of the pot. The jackhammer is raised and lowered by an air cylinder. Both the cylinder and jack hammer are powered with compressed air and require the use of a solenoid-operated directional control valve to make them function.

The problem

For years, the directional control valve was a major problem for the mill. Because the jackhammer performs a critical operation, when the valve failed the jackhammer became inoperable resulting in a crisis situation. A repair crew was called immediately to manually lift the jackhammer out of the molten aluminum so it was not destroyed, and the air valve was either replaced or repaired so the crane could be put back into service.

Old valves failed every day.

To understand the magnitude of the problem, it is helpful to explain that there are 348 pots on line No. 1 at the New Madrid smelter, all making aluminum 24 hours per day, 365 days per year. There are eight cranes with jackhammers to perform the crust-breaker function for all 348 pots. It is a continuous process, and to have a crane with a jackhammer down due to a failed air valve is an enormous and costly problem. In the past, each crane broke down three times, and sometimes four times, per day due to a failed valve. Some days the number was higher. This cost the plant $5,000 to $6,000 every day in parts and labor, not including lost production.

The primary cause of failing valves is high contamination of the compressed air. The raw products of alumina oxide and fluoride are taken into the compressed air system and delivered to the valves. These products are abrasive, corrosive, and found in abundance throughout the plant. And that is just part of the cause. South Missouri along the Mississippi River has a hot and humid climate. That means the compressed air carries a high level of moisture nearly year round. And to make the situation even worse, the plant is more than 40 years old, with compressed air lines that produce pipe scale that ends up in pneumatic components.

The pot rooms.

The pipe scale alone can make ordinary air valves fail regularly. Due to the volume of air used and the high contamination levels, and because the compressors are onboard the crane, filtering the air is not practical due to high cost and added maintenance. Although air filtration was tried, the maintenance crews found the air filters clogged up quickly and became inoperable in short order. The extreme contamination makes it virtually impossible to filter the air economically.

The solution

BJ Burks, the maintenance supervisor over the pot lines, was looking for a solution. He tried different internal valve materials and configurations, special seals, and air filtration in an effort to make the valves perform better. None of these worked out. Then Burks found an air valve made by AVENTICS Corp. (formerly Rexroth Pneumatics) that uses an entirely different technology from other air-valve manufacturers. This valve does not use a spool or a poppet, but instead uses sliding ceramic plates to control the air-flow direction.

The ceramic plates offer many advantages over spool valves. Because ceramic material is very hard, contamination has no effect on the plates. The design uses two ceramic plates placed one on top of the other. A ceramic-to-ceramic seal is formed where the plates fit together, thus eliminating any clearance for contamination to lodge like that found in spool or poppet valves. This is what causes jamming. Contamination passes through large slots in the ceramic plates and is either delivered to the cylinder or exits through the valve exhaust ports without getting a chance of causing the valve to jam. And there are no elastomeric seals in the critical area of the valve to wear or get damaged by the contamination. This combination of ceramic plates, a ceramic seal, and an extra-strong return spring makes for a very robust and dependable valve that will operate reliably under the most contaminated conditions.

Alumina oxide is taken into compressed air, jamming old valves.

Under AVENTICS' Discover the Ceramic Advantage Free Valve Program, Burks received for free a 1-in. ported single-solenoid Ceram valve to try. His goal was to reduce some of the failures that cause such a high level of problems. Burks thought if he could find a valve that would work for two or three days without failing, then his difficult situation would be much improved. After one week of operation, Burks was asked how the valve was performing. His reply was, "Doing great and firing on all cylinders." After two weeks, he was asked again how the valve was running. He said, "Like a good watch."

By this time, Burks knew he had found the solution to his problem. The AVENTICS Ceram air valve was performing as promised. The ceramic plate technology survives the contamination, survives the heat, and withstands the harsh and abusive conditions inherent in his process on the pot lines. He began replacing all the jackhammer valves with the Ceram valve, and after two weeks the full replacement was completed.

Resulting impact and implications

Since switching to the Ceram valve, performance has improved from many failures per day on the old valve to zero failures in the three months the valve has been in operation. They are enjoying very large cost reductions not only from the labor savings but from valve replacement costs they no longer have. The Ceram valve cost is 70% lower than the valve they used in the past, and there are no valve repair costs either. Production is up, which makes everyone happy. Because there have been no failures of the Ceram valve, maintenance teams are now free to engage in preventive, predictive maintenance instead of reactive maintenance -- which is a goal of high importance for Burks and his team. This helps to keep the plant running more efficiently, reduces costs, and improves morale of the maintenance teams. Morale is up also with the crane operators who say they can now do their jobs more efficiently because they no longer have to take the cranes out of service because the Ceram valves work every time.

Jackhammer.

Burks was asked if he could describe in one word the biggest benefit the Ceram valve has brought him so far. He thought for a moment and said, "Reliability. Reliability of the cranes has improved significantly. The result was immediate. This is big, real big. It means less down time, more uptime, and higher equipment availability to the process. The cranes are much more productive now that they have air valves that do not fail. The payoff is huge. Labor costs are down. Maintenance time is down. Material usage is down. Overall productivity has improved. Performance and uptime has greatly improved, and there is less waste of material."

He mentioned another component that was key to making the change to the Ceram valve: availability. The old valves have a long lead time. Even repair parts are difficult to get delivered. A local AVENTICS distributor has the Ceram valves in stock, making for quick delivery day or night.

Burks has already identified other areas of the plant that can benefit from the Ceram valve. The conditions may not be as harsh, but the payoff comes from the high-cycle-life capability of the valve. One of the many features as stated in the AVENTICS catalog is an expected service life that exceeds 150 million cycles. It has been known to reach 400 million cycles. The end result is fewer air-valve failures, less replacement costs, reduced downtime, and higher productivity.

Source: AVENTICS Corp. (formerly Rexroth Pneumatics)

Published November 2015

Rate this article

View our terms of use and privacy policy